Industrial thermal insulation is a vital component in industrial facilities and processes, playing a key role in controlling heat transfer, reducing energy consumption, and enhancing safety. By creating a barrier against heat transfer, these materials help maintain the desired temperature in industrial equipment and prevent energy loss.

Definition, Importance, and Types of Industrial Thermal Insulations

Industrial thermal insulation refers to materials that, due to their low thermal conductivity and resistance to high temperatures, can prevent heat transfer between two environments. This characteristic makes these materials crucial for energy conservation and temperature control in various industrial processes.

The Importance of Thermal Insulation in Industry

The use of thermal insulation in various industries offers numerous benefits, the most important of which include:

- Energy Savings: Proper insulation of equipment and pipes can reduce fuel consumption by up to 40%.

- Increased Safety: By preventing equipment surfaces from becoming dangerously hot, it protects personnel from burns and prevents accidents.

- Precise Temperature Control: Insulation helps maintain the temperature required for optimal performance of industrial processes.

- Reduction of Environmental Pollution: By reducing fuel consumption, greenhouse gas emissions are also significantly decreased.

- Increased Equipment Lifespan: Protecting facilities from temperature fluctuations extends their useful life.

Types of Industrial Thermal Insulations

Industrial thermal insulations are classified into different categories based on their structure and constituent materials, with fibrous insulation being one of the most important.

1. Fibrous Insulation

This category of insulation is composed of fine, interwoven fibers and effectively prevents heat transfer due to its porous structure.

- Fiberglass:

This insulation is produced by melting glass and turning it into fine fibers. Fiberglass can withstand temperatures up to 450°C, but its optimal operating temperature range is up to 250°C. Due to its affordable price, easy installation, and moisture resistance, it is widely used for insulating piping, tanks, and air ducts. - Rock Wool/Mineral Wool:

Rock wool is produced from molten volcanic rocks such as basalt and is one of the most commonly used insulations in various industries. This insulation has very high thermal resistance and can withstand temperatures up to 600°C. Due to its high fire resistance, excellent sound insulation properties, and chemical stability, rock wool is used for insulating furnaces, boilers, and petrochemical equipment.

2. Ceramic Insulation

This type of insulation is designed for very high-temperature applications and exhibits exceptional thermal resistance.

- Ceramic Fiber:

Ceramic fiber can withstand temperatures up to 1420°C, which is why it is used in sensitive industries like steel and aluminum manufacturing for insulating furnaces. The main advantages of this insulation include outstanding thermal resistance, low weight, and high resistance to thermal shock. - Insulating Fire Bricks:

These bricks, which can withstand temperatures up to 1700°C, are known as one of the most durable options for constructing furnace walls and combustion chambers. High mechanical strength and long-term durability are prominent features of insulating fire bricks.

3. Foam Insulation

Foam insulations are widely used, especially for preventing cold loss and controlling moisture, due to their closed-cell structure and high insulation coefficient.

- Polyurethane:

This foam is effective in a temperature range of -40°C to +120°C and is an ideal option for cooling systems and chemical storage tanks due to its high insulation coefficient and excellent moisture resistance. - Polyisocyanurate:

This insulation, which is resistant up to 150°C, is primarily used for insulating industrial roofs and exterior building walls due to its good fire resistance and dimensional stability.

Applications of Industrial Thermal Insulation in Various Industries

Thermal insulation is a fundamental requirement in many large industries, helping to control processes and increase safety.

Steel and Metals Industries:

Equipment such as electric arc furnaces, blast furnaces, and casting machinery operates at extremely high temperatures and requires insulation with exceptional thermal resistance. For this reason, ceramic fibers and refractory bricks are most commonly used in these industries.

Oil, Gas, and Petrochemical Industries:

In these industries, thermal insulation is vital for maintaining the temperature of fluids in crude oil transfer pipelines, chemical reactors, and storage tanks. Here, the use of insulations that are resistant to chemicals and high temperatures is particularly important.

Cement and Glass Industries:

In these industries, equipment like cement rotary kilns and glass melting tanks operate under extremely high heat and severe abrasive conditions. Therefore, selecting insulations that are resistant to both high temperatures and abrasion is essential.

Power Plants and Power Generation:

To increase efficiency, reduce heat loss, and prevent damage to sensitive equipment and instrumentation in power plants, industrial thermal insulation is widely used in power plant boilers, and the casings of steam and gas turbines.

Key Criteria for Selecting Industrial Thermal Insulation

Choosing the right insulation requires a careful examination of technical parameters and environmental conditions. The most important criteria are:

- Thermal Resistance (R-Value): This parameter, denoted by the R-value, is the primary indicator of insulation performance. The higher the R-value, the greater the insulation’s resistance to heat transfer and the better its performance.

- Thermal Conductivity (λ-Value): This coefficient, represented by the symbol λ (lambda) and measured in W/m.K, indicates the rate of heat transfer through a material. For an ideal insulator, this coefficient should be as low as possible.

- Temperature Resistance: The maximum temperature that the insulation can continuously withstand must be compatible with the operating temperature of the equipment. Temperature ranges are typically categorized as follows:

- Low temperatures: Up to 200°C

- Medium temperatures: Between 200°C and 600°C

- High temperatures: Between 600°C and 1200°C

- Ultra-high temperatures: Above 1200°C

- Chemical Resistance: In corrosive industrial environments, the insulation must be resistant to chemicals such as acids, bases, and organic solvents to avoid structural degradation.

- Mechanical Strength: The insulation must have the ability to withstand applied mechanical loads in terms of compressive, tensile, and flexural strength to avoid fracture or deformation over time.

Installation Techniques for Industrial Thermal Insulation

Proper installation of insulation is as important as its selection, and different techniques are used based on the type of equipment:

- Pipe Insulation: Pre-fabricated shells matching the pipe diameter are typically used for this purpose. They are secured with special adhesives and finally covered with an aluminum sheet layer for physical protection.

- Tank Insulation: Depending on the conditions, various methods are used, such as installing multiple layers of insulation (layered method), injecting foam into the empty spaces between walls (injection method), or using pre-fabricated insulation panels.

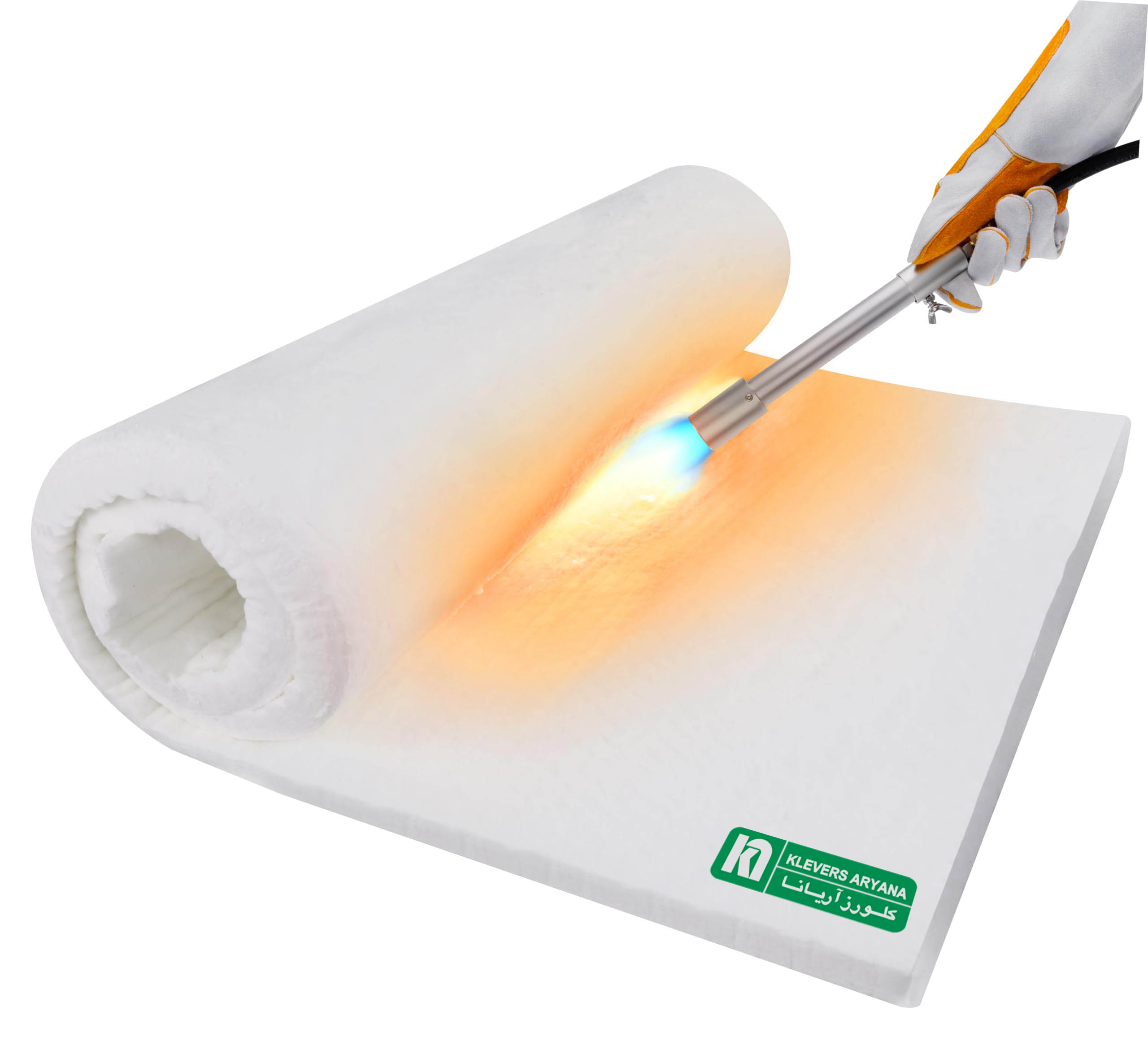

- Furnace Insulation: For furnaces operating at very high temperatures, techniques such as installing ceramic modules, using fibrous refractory blankets, and applying protective coatings are employed to increase the durability and efficiency of the insulation.

- Rotating Equipment Insulation: Such as turbines and compressors, where maximum temperatures of 700°C are insulated using various methods (including jacket thermal insulation).

Standards and Regulations

Specific standards and regulations have been developed to ensure the quality and safety of insulation systems.

- International Standards:

Reputable standards such as ASTM C177 for measuring thermal conductivity, ISO 8497 for general specifications of thermal insulations, EN 13162 for mineral insulation requirements, and ASTM C518 for testing thermal properties are recognized as industry benchmarks. - Safety Regulations:

Compliance with safety regulations such as OSHA standards for workplace safety, NFPA codes for fire protection, and specialized API standards for the oil and gas industries is essential in all stages of insulation design and implementation.

Advantages and Challenges of Industrial Thermal Insulation

- Advantages:

Implementing an efficient insulation system brings significant benefits. It can reduce energy consumption by 30% to 50%, and the return on investment is typically achieved in less than two years. Additionally, by lowering the temperature of hot surfaces, workplace safety is increased, carbon dioxide (CO₂) emissions are reduced, and the control of industrial processes is improved. - Challenges:

Despite the numerous advantages, implementing insulation projects also comes with challenges. High initial costs, complexities in engineering design, the need for a specialized workforce, and maintenance and repair costs are among the main obstacles. Furthermore, considering environmental issues, the disposal conditions for used insulation materials must be assessed based on the type of insulating material, which in itself is a significant constraint.

Innovations and New Technologies

Industrial thermal insulation is constantly evolving, and new technologies are being developed to improve performance.

- Nano-insulations: The use of nanomaterials has made it possible to produce insulations with much smaller thicknesses and superior thermal performance.

- Smart Insulations: These insulations can automatically adjust their thermal properties based on changes in environmental conditions.

- Insulating Paints: These nano-coatings not only create a thermal insulation layer but also protect surfaces from corrosion.

- Jacket Thermal Insulations: These are calculated, designed, and implemented based on the dimensions and thermal conditions of the equipment.

Maintenance and Repair of Industrial Thermal Insulation

Regular inspection and maintenance are essential to maintain the efficiency of the insulation system.

Repair and Reconstruction: Depending on the severity of the damage, actions can range from local repair of minor damages to replacing worn-out sections or, if necessary, a complete overhaul of the insulation system.

Periodic Inspection: It is recommended to conduct a visual inspection every six months, a thermal test annually, and an insulation thickness measurement every two years.

Signs of Deterioration: Cracking of the insulation surface, an unusual increase in external surface temperature, moisture leakage, and discoloration of the protective coating are all signs of deterioration and reduced insulation efficiency.

Case Study: Optimizing Insulation in a Refinery

In a case study, an oil refinery faced a significant challenge with high heat loss in its crude oil transfer lines. This problem had led to a 25% increase in energy consumption in this industrial unit. To solve this issue, after conducting detailed thermal analyses on the existing pipelines, a multi-layer industrial thermal insulation system was designed and implemented. In this project, 100 mm thick rock wool was used as the main insulation layer, and finally, a weather-resistant aluminum coating was installed for physical protection. The implementation of this solution yielded remarkable results; heat loss was reduced by 35%, leading to annual savings of $2 million for the refinery. This investment was recovered in 18 months and also contributed significantly to a 40% reduction in greenhouse gas emissions.

Frequently Asked Questions (FAQ)

- What factors are important in choosing thermal insulation?

The most important factors for selecting suitable insulation include the operating temperature range, chemical resistance to corrosive materials, thermal conductivity coefficient, mechanical resistance to pressure and impact, and the final cost of the project. - Is insulation effective in all seasons?

Yes, thermal insulation has a dual function. In the summer, it prevents ambient heat from entering the system, and in the winter, it prevents heat from escaping and energy loss. - What is the lifespan of thermal insulations?

The useful life of insulations varies, typically between 10 to 30 years, depending on the type of material, quality of installation, and the environmental conditions in which they are used. - Does installing insulation require a production shutdown?

In many cases, insulation work can be carried out without a complete production line shutdown, during scheduled periodic maintenance and repair programs, to avoid disrupting the production process.

Conclusion

Industrial thermal insulation is more than a technical necessity; it is a smart economic investment. The correct selection of insulation type, the engineering design of an efficient system, and its proper installation can lead to significant energy savings, increased workplace safety, and improved overall performance of industrial facilities. Given the global trend of rising energy prices and increasing environmental sensitivities, the importance of thermal insulation will become even more apparent in the future, and investing in new technologies in this field can provide a sustainable competitive advantage for industries.

About Klevers Aryana Company

Klevers Aryana Company, with over two decades of specialized experience in the production and supply of industrial thermal insulation materials, is recognized as one of the leading companies in this field in Iran. The company covers the diverse needs of industries by offering a variety of products and services.

Klevers Aryana’s products and services include pillow-type jacket insulations for pipes and equipment, cladding-type jacket insulations for heavy industrial applications, and specialized valve insulations for industrial valves. In addition to manufacturing, the company also provides comprehensive services such as technical consulting, insulation system design, and installation and commissioning by a team of experts.

Reasons for choosing Klevers Aryana include the guaranteed quality of products compliant with international standards, competitive pricing and flexible payment terms, strong after-sales service and technical support, and fast delivery of orders across the country. For a free consultation and more information, you can contact the company’s experts.

Sources:

- U.S. Department of Energy – Insulation Materials Guide

- Johns Manville Industrial Insulation Technical Data

- NUTEC Industrial Thermal Insulation Solutions

- ASTM International Standards for Thermal Insulation

- International Energy Agency – Industrial Energy Efficiency Report

- Thermal Insulation Material Market Analysis 2025-2030

- ISO Standards for Industrial Insulation Systems