In the beating heart of modern industries, where heat, energy, and precision are paramount, industrial thermal insulation is a silent hero. This engineered process not only prevents the loss of billions of dollars in energy but also ensures the safety of personnel and the stability of expensive equipment. However, the backbone that holds this vital system together is a set of precise codes and technical specifications known internationally as Industrial Insulation Standards.

This article is not a general guide; it is a detailed breakdown of the most important standards from the ASTM organization that every engineer, project manager, and technical specialist in the field of industrial insulation must be intimately familiar with.

Why should we know the details of industrial insulation standards?

Knowing the name of a standard is not enough. Understanding its details empowers you to:

- Assess true quality: Determine whether a product merely carries a standard’s label or truly meets its technical requirements.

- Prevent costly errors: Choosing the wrong jacket can lead to Corrosion Under Insulation (CUI), reduced efficiency, and safety hazards.

- Have a common language with your supplier: By mastering the technical details, you can accurately communicate your needs to the supplier.

A Breakdown of Key ASTM Standards for Insulation Jacketing

The cover or jacket is the first line of defense for an insulation system. Below, we delve into the technical details of the most important ASTM industrial insulation standards in this area.

1. ASTM C921: The Cornerstone of Jacket Specifications

This standard sets the general rules of the game. ASTM C921 is not just a name but a collection of physical and material requirements for jackets.

- What does it cover? Various types of jackets used over pipe and equipment insulation.

- Key Details: This standard defines limits and test methods for jackets regarding:

- Tensile Strength: The minimum force the jacket can withstand before tearing.

- Puncture Resistance: The ability to resist sharp impacts.

- Water Vapor Permeance: The rate at which moisture passes through the jacket, which is crucial for preventing Corrosion Under Insulation.

- Service Temperature Range: The minimum and maximum temperatures the jacket can endure without losing its properties.

2. ASTM C1729: The Specialized Standard for Aluminum Jacketing

Aluminum is a popular choice due to its corrosion resistance and good appearance.

- What does it cover? Specifically, aluminum sheets used as a protective covering.

- Key Details:

- Alloy and Temper: This standard recommends specific alloys like 3003 or 3105 and a temper of H14, which offers the best combination of formability and strength.

- Moisture Barrier Coating: It mandates that the inner side of the aluminum sheet must have a protective layer (such as polysurlyn or kraft paper) to prevent galvanic corrosion with the metal surface of the equipment.

3. ASTM C1879: Installation Guide

The best jacket in the world is useless if installed improperly. This industrial insulation standard focuses on the “how-to” of installation.

- What does it cover? Procedures and requirements for installing metal jacketing over insulation.

- Key Details:

- Overlap: Specifies the minimum amount (e.g., 2 inches or 5 cm) that each piece of jacketing must overlap the next to prevent water ingress.

- Type and Spacing of Fasteners: Defines the specifications for screws or bands used to secure the jacket and the maximum allowable distance between them.

- Sealing: Requires the use of sealants at all joints and edges to create a completely waterproof system.

The Golden Standard for Jacketed Insulation: ASTM C1695

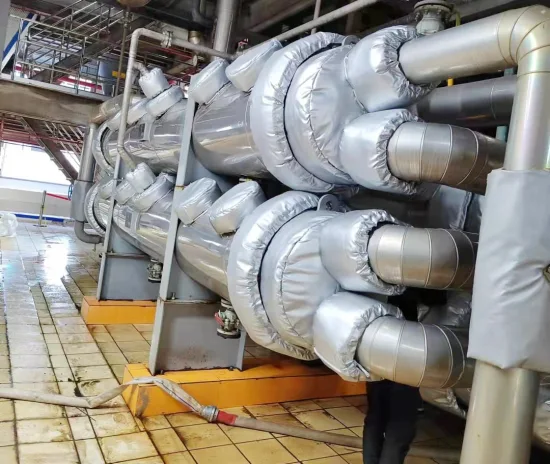

This industrial insulation standard is directly related to the heart of Klevers Aryana’s specialized products: reusable jacket and pillow insulation. These products are designed for equipment such as valves, flanges, pumps, and turbines that require frequent inspection and maintenance.

ASTM C1695 is a specification for the fabrication of flexible, removable, and reusable insulation for hot service.

Let’s break down this standard layer by layer:

- Outer Jacket:

- Material: The standard specifies materials like silicone-coated fiberglass fabrics.

- Requirements: The outer layer must be resistant to weather conditions, UV radiation, water, and oil, and possess sufficient mechanical strength to withstand repeated openings and closings.

- Inner Liner:

- Material: This layer, which is in contact with the hot surface, must be made of materials with very high thermal resistance, such as silica fabrics or Stainless Steel Mesh. This is particularly important in turbine insulation and high-temperature equipment.

- Requirements: Resistance to the maximum process temperature without degradation.

- Insulation Fill:

- Material: Typically, needled fiberglass mat, ceramic wool, rock wool, or more advanced materials like Aerogel are used.

- Requirements: Very low Thermal Conductivity to minimize heat loss. The thickness of this layer is determined based on thermal calculations.

- Fastening System:

- Material: The standard refers to various fastening systems such as woven straps with D-ring buckles, lacing hooks with refractory wire, or industrial-grade hook-and-loop fasteners (like Velcro).

- Requirements: The fastening system must be secure, adjustable, and heat-resistant to ensure a complete and seamless fit of the insulation on the equipment.

Strict adherence to all these details in the ASTM C1695 standard ensures that the manufactured jacketed insulation not only has outstanding thermal performance but also maintains its durability and effectiveness for years of continuous industrial use.

Conclusion

Mastering the technical details of international industrial insulation standards transforms you from a mere buyer into an informed technical partner. This knowledge allows you to select insulation solutions not based on claims, but on engineering evidence and true compliance with global regulations. This approach is the best guarantee for achieving energy efficiency, sustainable safety, and a rapid return on investment.

Klevers Aryana: Commitment to Standards, Expertise in Execution

At Klevers Aryana Company, we don’t just see standards as a requirement; we see them as the DNA of our products. With over two decades of experience, we specialize in the design and manufacture of various industrial thermal insulations, especially reusable jacketed insulation, and we are proud to state that our products are made in full compliance with the technical details of standards such as ASTM C1695.

Our Products and Services, More Than Just a Product:

- Jacket and Pillow Insulation: An ideal and standard-compliant solution for gas and steam turbines and compressors in power, oil & gas, and petrochemical industries, as well as for valves, flanges, and equipment requiring quick access.

- Metal Cladding Systems: Robust metal coverings for the long-term protection of pipelines and tanks.

- Precise Consultation and Engineering: Our technical team, with its mastery of standards, assists you in selecting and designing the most optimal insulation system.

- Design and production of various PFP insulations: as protective and fire-resistant insulation.

To discuss the technical details of your next project and receive a consultation that makes a difference, contact our experts today via our Contact Us page.