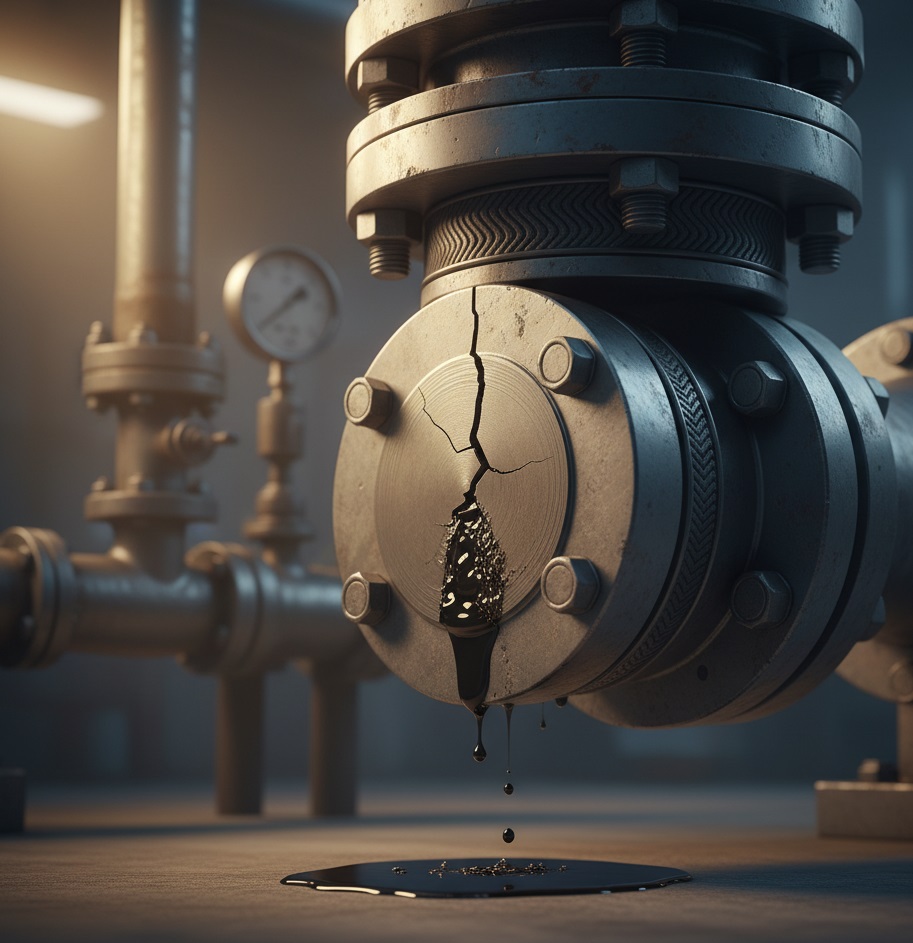

Have you ever faced this engineering nightmare? You shut down the pipeline, replace the old gasket with a new and expensive one, tighten the bolts with a torque wrench, but as soon as the system pressure increases, the fluid starts dripping between the flanges again. This scenario (flange leakage) is one of the most common and yet most costly challenges in the petrochemical, oil, gas, and power plant industries. But why? Isn’t the gasket new?

The truth is that the gasket is only part of the sealing equation. In many cases, replacing a gasket without paying attention to the condition of the “flange face” and the thermodynamic conditions of the system is like putting a band-aid on an infected wound; it covers the appearance but does not solve the problem.

In this specialized article from Klevers Aryana, we examine 5 hidden reasons for flange leakage that are often overlooked and introduce a modern solution for damaged surfaces.

1. Flange Face Damage

The most important reason why gasket replacement doesn’t work and causes flange leakage is the existence of defects on the surface where the gasket sits. The ASME PCC-1 standard clearly states that the flange face must have a specific roughness so that the gasket can flow into its microscopic grooves and complete the sealing.

However, over time, factors cause the degradation of this surface:

- Chemical Corrosion: Acidic or alkaline fluids eat away the metal surface.

- Mechanical Scratches: Deep grooves are created when cleaning the flange with sharp tools.

- Pitting: Small holes caused by rust.

If there is a radial scratch (from center to outside) on the flange face, even the best spiral wound gaskets cannot prevent the fluid from escaping.

Proposed Solution: Using High-Temperature Sealant Pastes

In cases where re-machining (Re-facing) the flange is not possible or the cost of line shutdown is very high, using filling compounds and industrial refractory adhesives is one of the ways.

This is where a product like High-Temperature Two-Component Adhesive (Klevers Paste) proves useful. This product not only acts as a sealing supplement, but by filling the voids and pores of the flange surface, it creates an integrated and heat-resistant base on which the gasket can sit well.

2. Bolt Relaxation or Creep

Even if the gasket and flange are healthy, if the clamping force is not maintained, leakage will occur. A phenomenon called Creep at high temperatures causes the bolts to stretch slightly over time and the holding force to decrease.

- Thermal Fluctuations: Continuous heating and cooling (Thermal Cycling) causes expansion and contraction of the flange and bolts.

- System Vibration: Vibrations from pumps and compressors loosen the nuts.

Technical Note: Using spring washers (Belleville washers) and selecting gaskets with a high recovery rate can reduce this problem. Also, to get familiar with vibration-resistant materials, we suggest reading our article on industrial refractory fabrics to get to know the base fibers of this equipment. Also, read more about expansion joints here: Fabric Expansion Joints (Expansion Joints).

3. Improper Gasket Material Selection (Material Incompatibility)

Sometimes engineers select gaskets based only on “temperature”, but ignore “pressure” and “chemical compatibility”.

- A graphite gasket may withstand the temperature, but if it is in a strong oxidizing environment, it will turn to powder.

- Rubber gaskets become dry and brittle at temperatures above 120 degrees Celsius.

For environments with very high temperatures requiring mechanical resistance, the use of ceramic-based or reinforced fiberglass materials is essential.

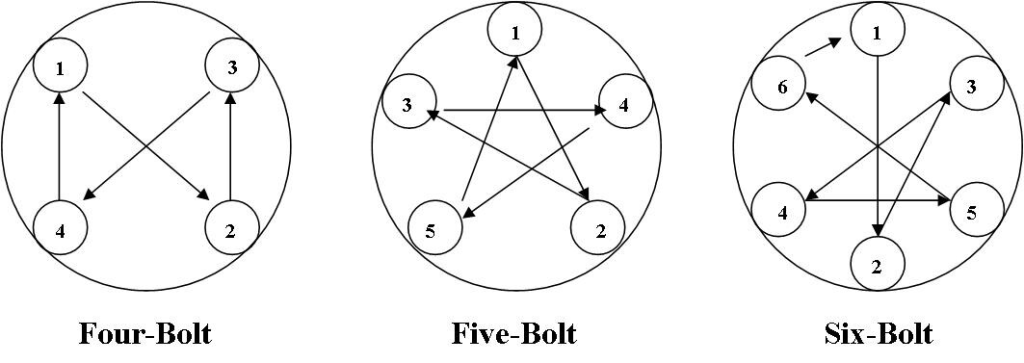

4. Uneven Load Distribution (Uneven Bolt Loading)

One of the common mistakes of novice technicians is not following the star pattern tightening pattern. If you tighten the bolts in a circular order, the gasket will be crushed on one side and gapped on the other.

Result? The crushed gasket (Crushed Gasket) loses its elasticity and leakage becomes inevitable.

5. Flange Misalignment (Misalignment)

If the two opposing flanges are not exactly parallel (Centerline High/Low) or the bolt holes are not facing each other (Rotational Misalignment), forcing them together with bolts wastes the elastic energy of the gasket. This residual stress causes the connection to open at the first opportunity (temperature or pressure increase).

Special Solution for Flange Leakage

In many overhauls, we encounter flanges whose surfaces have severe pitting or warping, and replacing the flange is not possible. In these conditions, using a liquid or paste sealing compound alongside a solid gasket is the gold standard of modern repairs.

Product Introduction:Two-Component Klevers Adhesive (KLEVERS Paste)

This product is an engineered refractory adhesive/paste designed exactly for such challenges.

Why is Klevers Paste 101 a suitable solution for preventing flange leakage? ?

- Extraordinary Temperature Tolerance: This product is designed to operate in high-temperature conditions and does not lose its structure.

- Micro-filling: Unlike solid gaskets that sit only on the peaks of the metal surface, this paste enters the tiniest scratches and corrosion pits and blocks the fluid’s escape path.

- Adhesion to Various Materials: Whether your flange is steel or cast iron, this product creates excellent adhesion.

- Suggested reading: Corrosion repair paste

Conclusion

Flange leakage after gasket replacement is not a sign of poor gasket quality; rather, it is a warning that your connection system (flange face, bolts, or alignment) is defective. By inspecting the flange surface according to standards and using modern products like Chlorz two-part adhesive to repair surfaces and reinforce sealing, you can reduce production line downtime costs to zero.

Remember, a thin layer of engineered paste can stop billions in leaks.

About Klevers Aryana Company (Klevers Aryana)

Klevers Aryana Company, with over two decades of brilliant experience, is a leader in the supply and production of the most specialized refractory materials, thermal insulations, and industrial sealing systems in Iran. By combining world-class technical knowledge and high-quality products, we are a reliable partner for the country’s oil, gas, petrochemical, and steel industries.

From advanced refractory adhesives to various thermal textiles, our engineering team is ready to provide precise technical consulting to solve your thermal challenges.

Technical Consultation and Price Inquiry:

To receive guidance on choosing the best sealing method and purchasing Chlorz two-component adhesive, contact our experts right now.

>> Contact Us and Free Consultation <<

References and Sources (References)

- ASME PCC-1-2019: Guidelines for Pressure Boundary Bolted Flange Joint Assembly. Link to ASME

- Fluid Sealing Association (FSA): Gasket Installation Procedures.

- European Sealing Association (ESA): Flange Surface Finish Recommendations.

- Brown, W. (2008). The Chronicles of Bolt Relaxation. Sealing Technology Journal.

- Klevers Aryana Technical Datasheets (Product 101).